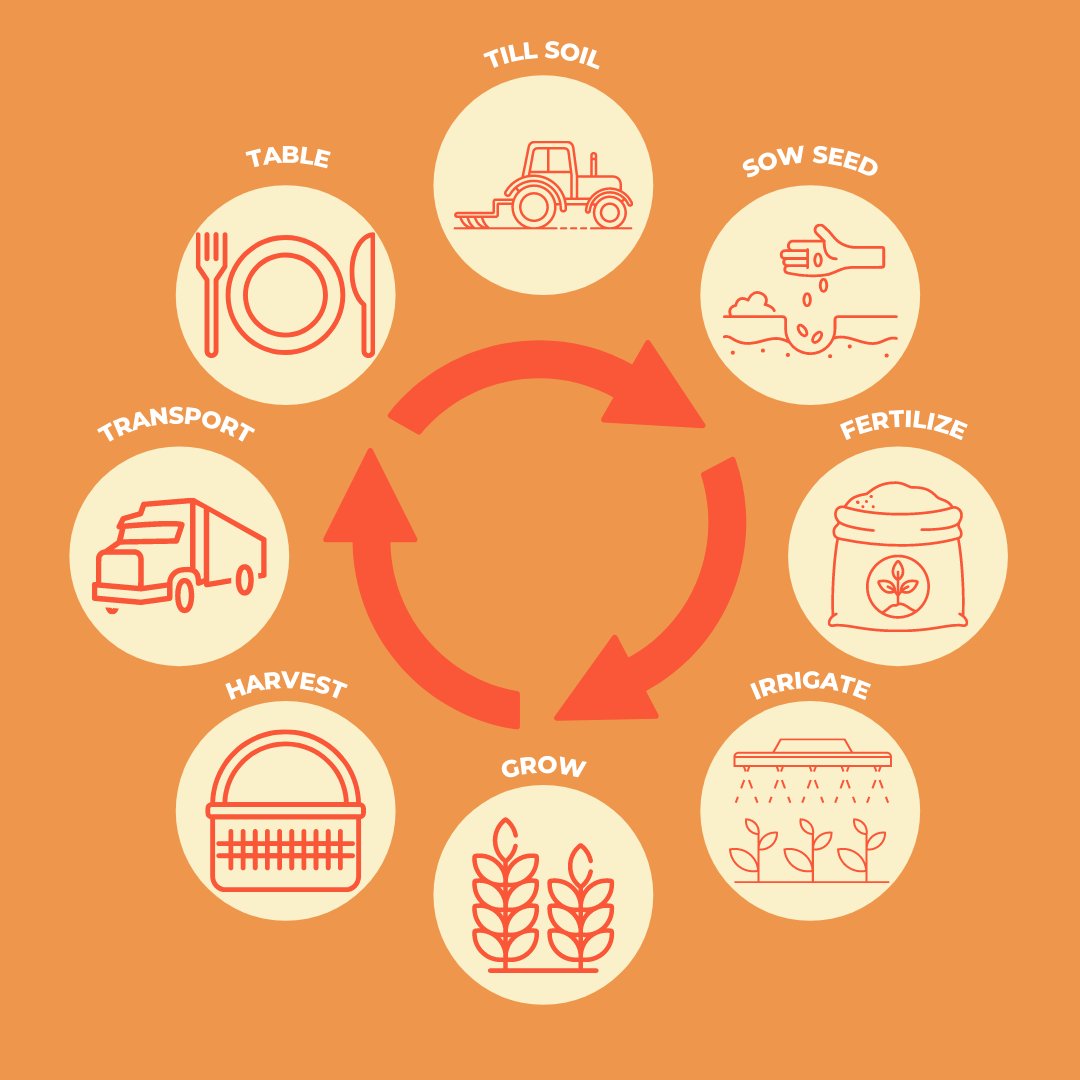

From FARM to the TABLE. How do you harvest your crops in a clean, green, and lean way?

#leansixsigma #leantraining #agriculture #problemsolving #rootcauseanalysis #waste #8wastes #washingtonagriculture #whatcomfarmfriends #eatlocal #farmtotable

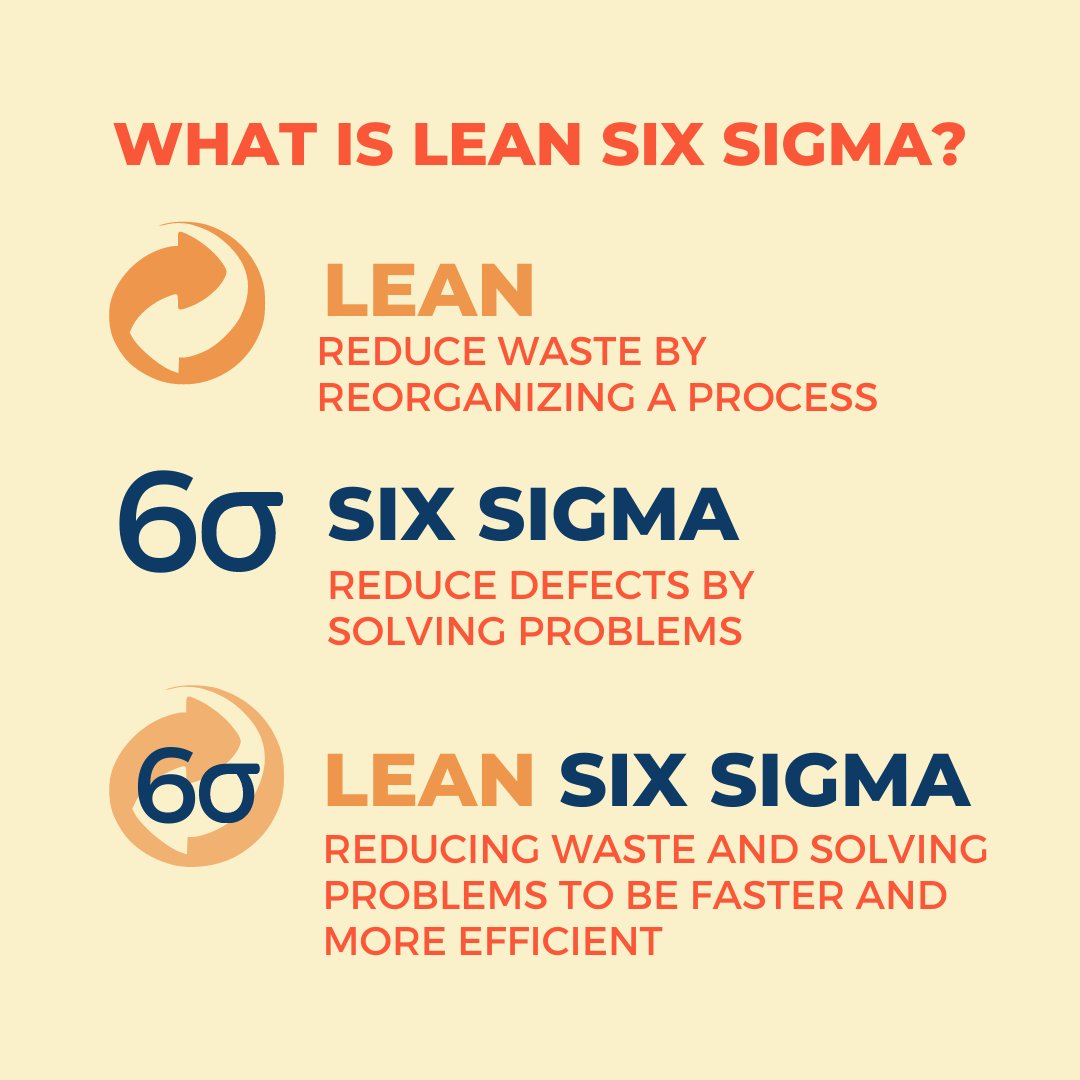

'Lean is learning to see waste. The moment you begin to see waste, everything else will take care of itself.' - Paul Akers

#lean sixsigma #8wastes #problemsolving #lean training #6sigma #sixsigma #lean #rootcauseanalysis #waste

We want you to have more time too! Lean helps you get your work done swiftly and efficiently, so you have more time to enjoy your hobbies!

#leantraining #leansixsigma #sixsigma #6sigma #productivity #efficiency #problemsolving #kaizen #8wastes #summer #summer 2021

This isn't only a waste of product, but a waste of profit. With Lean Six Sigma learn how to simply and reliably get your food to market!

#agriculture #problemsolving #rootcauseanalysis #leansixsigma #waste #8wastes #washingtonagriculture #whatcomfarmfriends #eatlocal

Whether your food is flying or falling, neither of those make it to the customer. Call us to help organize your production floor and optimize flow.

#whatcomcountyfarms #agriculture #eatlocal #optimize2021 #problemsolving #rootcauseanalysis #8wastes #leansixsigma

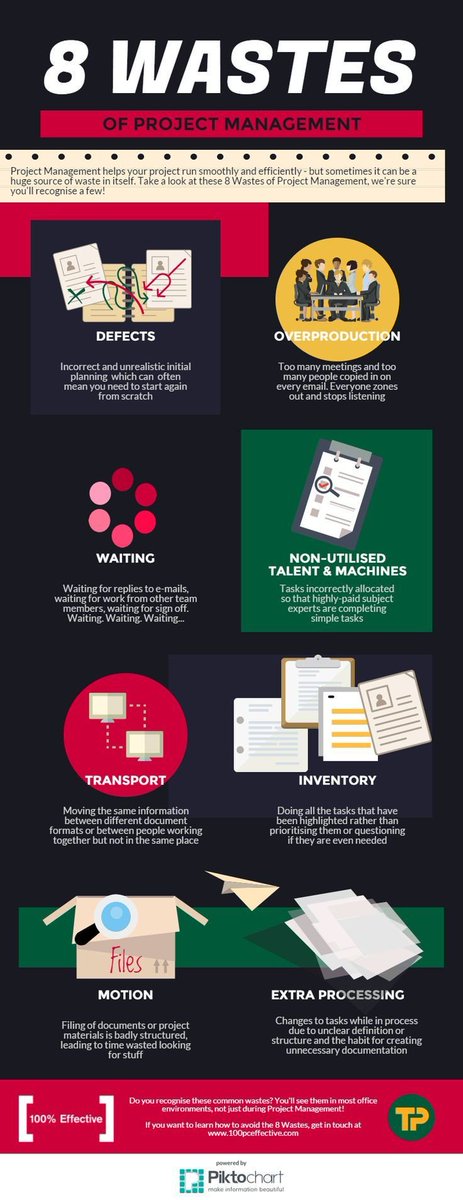

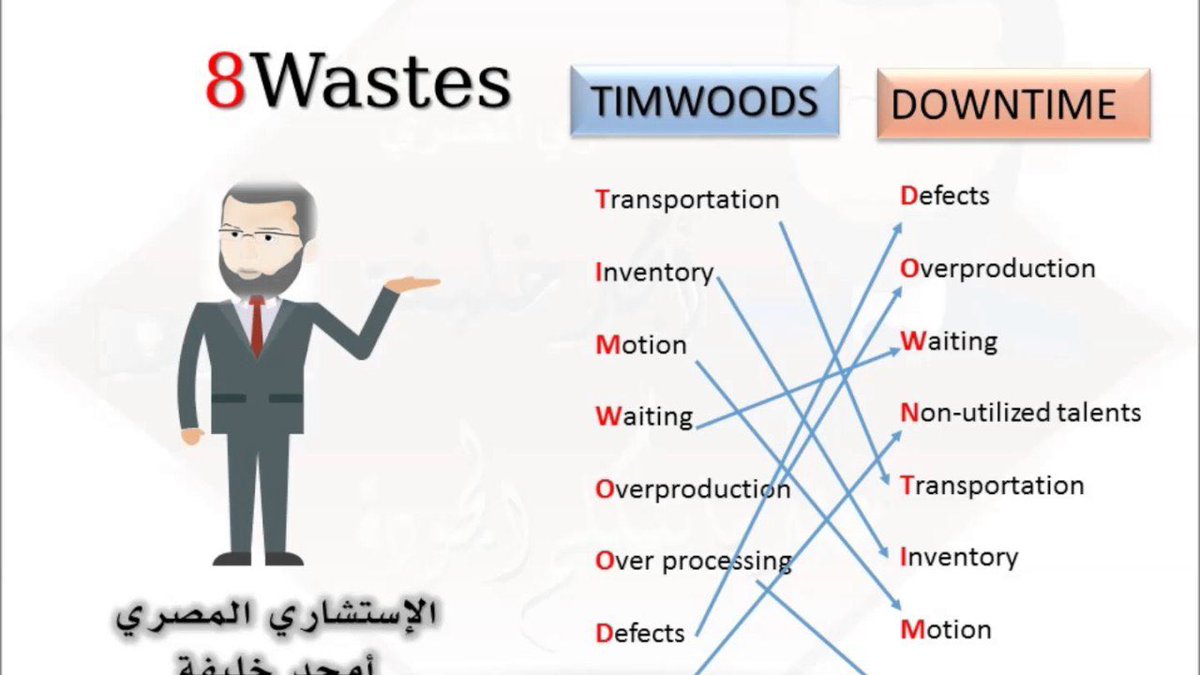

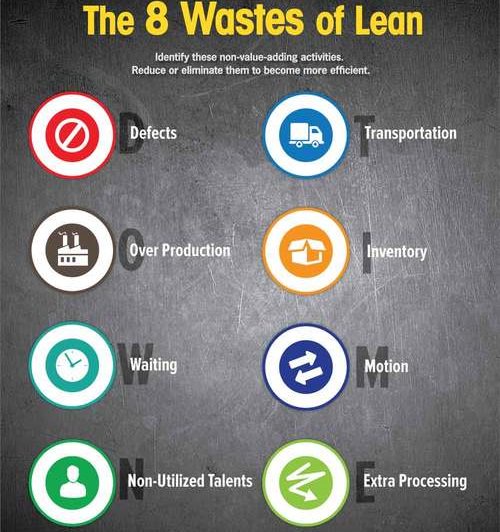

The 8 Wastes of Lean, also known as the acronym DOWNTIME, are the categories in operations where problems occur.

Identifying these wastes is the first step in saving your company’s money, time, and future.

#8wastes #waste #problemsolving #rootcauseanalysis #leansixsigma #6sigma

Getting your harvest quicker, safer, and cleaner is the difference between being in the grocery store or in the garbage. Lean is the proven methodology to remove waste in your process to create the “grocery store” reality

#leansixsigma #8wastes #washingtonagriculture

Check out this AMAZING improvement & video editing skills from our flow project engineer, so much motion eliminated!!!👍👏

#lean thinking #improvement #lean #8wastes #motion #continousimprovement

🔰 To help focus efforts in this area, Lean practitioners developed a list of eight wastes which establish the most likely areas where waste will occur.

👉 Read our blog to explore more: cannsult.org/post/what-are-…

#cannsult #consultingservices #8wastes oflean #8wastes #leanwastes

![Cannsult.inc (@cannsult) on Twitter photo 2023-07-21 13:38:54 📣 Discover the Power of Lean: Unraveling The 8 Wastes! 🚀

In our blog post, we delve deep into the world of Lean methodology and how identifying the 8 types of waste can revolutionize your business. 📈

👉 Read our blog: [cannsult.org/post/what-are-…]

#8WastesofLean #8Wastes #LISA 📣 Discover the Power of Lean: Unraveling The 8 Wastes! 🚀

In our blog post, we delve deep into the world of Lean methodology and how identifying the 8 types of waste can revolutionize your business. 📈

👉 Read our blog: [cannsult.org/post/what-are-…]

#8WastesofLean #8Wastes #LISA](https://pbs.twimg.com/media/F1kGqHsWIAE44Qm.jpg)